Asset Management

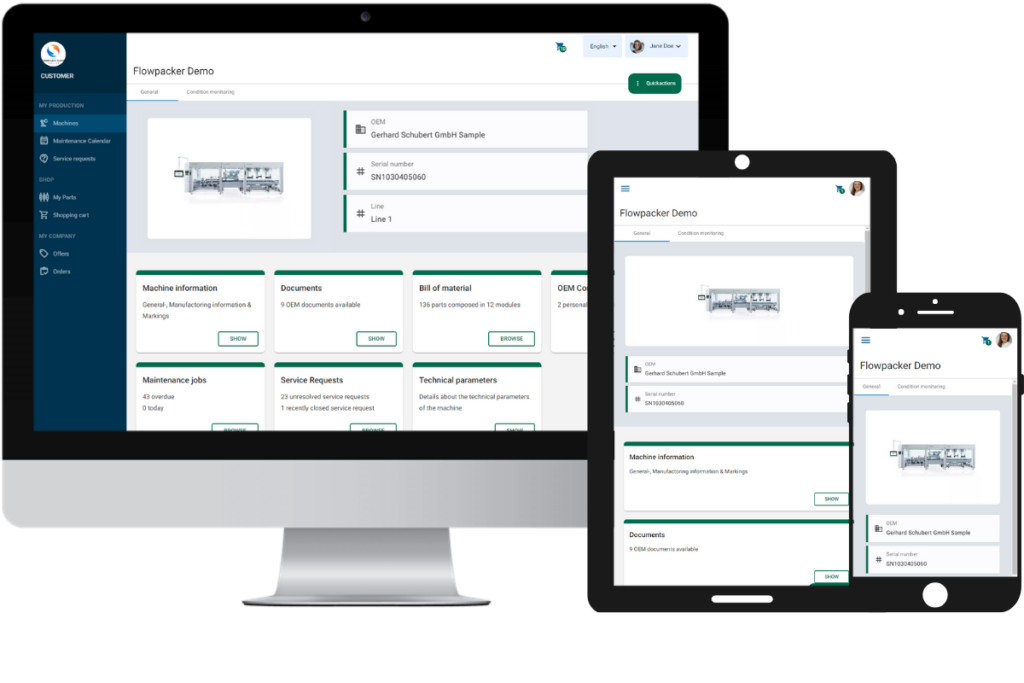

Today, your customers demand transparent 24/7 access to all information related to machines, plants, parts and associated documentation. With our customer platform, you offer your customers this place.

Our asset management is the core of our platform. Here, we bundle all information about your machines, spare parts and services in one place. With the digital machine file, the digital spare parts catalog and the provision of the digital twin, we create transparency and ensure the best possible customer experience.

More than a spare parts catalog

The components of our asset management

Our asset management goes far beyond a digital spare parts catalog. Because we have understood that requirements are diverse. That’s why our platform provides you with a comprehensive asset management system that bundles all information relating to machinery and equipment. The three components of our asset management are:

Digital

machine file

Digital spare

parts catalog

Digital

Twin

All relevant machine information for each individual machine is bundled in the digital machine file. From here, your customers and you as the manufacturer can call up all relevant machine data, such as manuals, technical specifications or parts lists.

The right spare and wear parts can be identified quickly and easily via the digital spare parts catalog. The integration of interactive 2D and 3D models as well as extensive visual navigation options further simplifies identification. In addition, the close link to the onlineshop ensures that spare parts can be placed in the shopping cart directly from the parts list.

As part of our asset management, we automatically generate the digital twin (asset twin) for each of your machines in the standardized data exchange format (AASX) of IDTA.

All data in a 360° view

with our asset management

Reliable and complete preparation of all important machine data forms the cornerstone for future success in mechanical engineering. With our asset management, you create maximum transparency of all relevant data. Master data, documents and instructions, which are often located in different places, are bundled and made accessible at any time. This gives dealers, customers, partners and employees a 360° view of all relevant data at all times. This includes:

- Master data of the machine

- Technical specifications

- Manuals and documentation

- Circuit diagrams

- Information on spare and wear parts

- Drawings, 2-D and 3-D models

- Machine relevant service information

- Performance parameters

The holistic view of all this information and the simultaneous dovetailing with all relevant after-sales service processes form the basis for the expansion of digital services. With this asset management strategy, you increase your efficiency and offer customers and partners the best possible and easy access to all machine-relevant data and information. This makes it easier for you to identify spare parts and receive maintenance instructions and service information more quickly.

Our Asset Management

all advantages at a glance

From asset management to

holistic after-sales management

However, providing the information alone is not enough to make you successful and competitive in manufacturing industry. That is why we can expand the functions on our platform step by step along our modules.

The very close integration of our asset management with the other modules of the platform enables us to provide you with optimum support for your customers and holistic after-sales management.

The close link between our asset management and the onlineshop enables, for example, the direct initiation of commerce processes. Through the connection to Customer Service, the digital service file can be accessed and, together with monitoring, the performance of a machine can be tracked. All relevant data and processes are processed and bundled together in the digital machine file. With the asset management from Transaction-Network, you have a well-functioning overall solution for your future success that is integrated into other processes.